How can we help you?

If you'd like to discover more about our company or our portfolio of services, you can find the right contact person here.

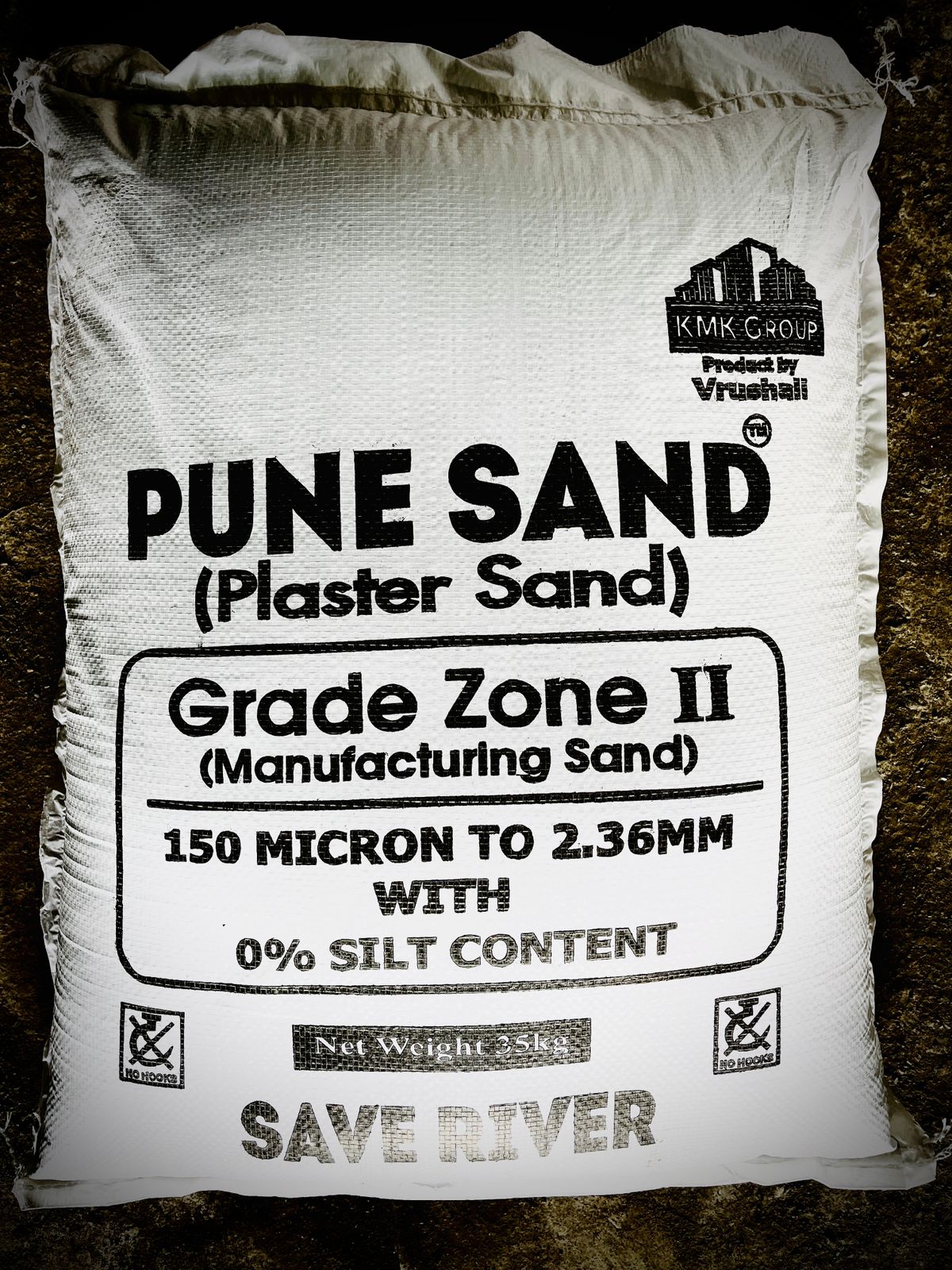

Contact UsProduct Description

Plaster sand is a very fine grade of sand that create smooth and even finish that can be used for filling cracks. As compare to River Sand, our sand has less impurities like silt, clay and organic matter, which can negatively impact the quality of the finished product. Secondly, River Sands are found in saline waters but our sands are treated and made in sweet waters along-with double washable processes. As a results, there are least chance of cracks and shrinks in walls. Besides Government recognition, and huge market penetration across Pune, Mumbai and Navi Mumbai, Plaster Washed Sand is one of the best products available for interior and exterior plasters. The molecular size between +75 microns to 2.36 mm ensures smooth finish to the walls

The mechanical grinding makes it suitable for best adhesive strength in the mortar mix. This further ensures minimum wastage of the material and labour due to impact rebound while plastering. Being the mechanically graded and washable sands; it does not need further screening or washing at site. Also pressurized water jets washes off the active minerals, thus diminishing the smoother finish. Plaster Sand is available throughout the year. It comes in the fresh gunny

bag packaging of various sizes.

Washed Plaster Sand are ensuring progressiveness in building material used for theprotective or decorative coating of walls and ceilings. Tremendous research are carried out in identifiying the role of specific shape of particle and gradation of fine aggregates which triggered the use of manufactured sand in the production of concrete. The complexity of construction and use of high

strength concrete in large number of buildings is the prime mover along with the scarcity of

river sand in many cities.

Our Services

Plaster Sand

Metal 10/20 MM

Crush Sand

Pune Sand Specification & Features

Pune Sand is produced by crushing large aggregate pieces, rock or quarry stones in a quarry or factory

Material Shape: Angular or Cubical

Texture: Rough

Material Size: 2.36 mm

Environmental Impact: Eco-Friendly

Features

Less moisture content

Unadulterated

Weather proof

Specifications & Use

Available in various packaging options.

Used for constructing roads, dams, houses, etc.

Why Only Pune Sand

- Better work-ability is guaranteed.

- Rich material imparts ease to masons to mix and use without re-bound loss.

- Thinner plaster guarantees much better coverage and crack-free surface.

- No cracks are generated as additives reduce the Hydration Heat of Cement.

- Excellent for internal & external plastering.

- Excellent strength due to cubical shape of the particles.

- Available round the year.

The Difference Between Pune Sand & Other Sand.

- Pune Sand

- Production possible as per demand.

- Clean sand and size of the particles of the sand similar.

- Use of Pune Sand is 100 percent.

- Professional and Proper Digging Methods

- Saves time and money.

- This Plaster is of Pune Sand Which has quality finish and easy to use

- Other Sand

- Limited stock so many obstacles.

- Wastage of sand because of variation in the size of the particles of sand.

- More wastage of sand.

- Digging of Rocks In Improper Way

- More time and money.

- This Plaster is of local brand which has improper finish and it has fear of falling